Ammonia Oxidation Process Catalyzed by Pt@XO2 (X = Ti, Zr, Ce, and Ce/Zr) Prepared by Photoreduction Process

Qiang Liu, Xueling Pu, Hairong Yue, Wei Jiang* and Bin Liang

Cite this: Ind. Eng. Chem. Res. 2018, 57, 7752−7763

https://pubs.acs.org/doi/10.1021/acs.iecr.8b00391

Abstract:

In the nitric acid industry, platinum loss is the second largest cost due to vaporization of the Pt gauze catalyst at high temperature. In this research, Pt is loaded on TiO2, ZrO2, CeO2, and ceria−zirconia solid solution by photoreduction and used as catalysts for ammonia oxidation. Results show that Pt content of the obtained catalysts is effectively reduced to 0.08 wt %, but their catalytic performance is better than that of the traditional Pt gauze between 300 and 800 °C. The best catalyst, 3Pt@CeO2 with 0.0797 wt % Pt content, enabled complete ammonia transformation at 300 °C and 80% NOx yield at 800 °C with the space velocity of 235 000 h−1 and the oxygen-to-ammonia ratio of 15 in ambient pressure. After 50 h of continuous operation, noobservable decay in performance was detected. Such excellent performance is ascribed to the lattice oxygen provided by CeO2 and the formation of Pt−Ce−O. These results provide a promising method of improving the current industrial Pt catalysts.

本工作采用光催化剂沉积技术于光催化剂TiO2, ZrO2, CeO2及铈锆固溶体表面负载微量的Pt,制备一系列氨氧化催化剂。在固定床反应器中,300℃实现NH3完全转化,有效减少反应过程中Pt耗。其中,Pt含量为0.0797 wt%的Pt/CeO2催化剂具有最佳性能。300℃时,NOx的选择性达到80%,连续使用50h,催化剂活性未见明显变化。高活性的根本原因在于CeO2丰富的氧空位和Pt-Ce-O键的形成。

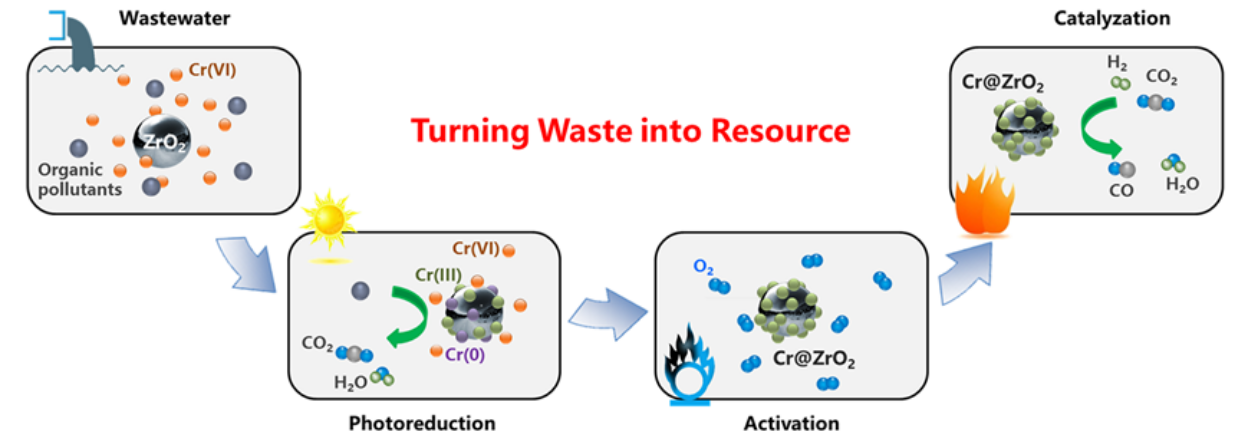

An Environment-Friendly Strategy for One-Step Turning Cr(VI) Contaminant into a Cr-Loaded Catalyst for CO2 Utilization

Wei Jiang,* Qiang Liu, Yang Tao, Kequan Mu, Zheng Wang, Yingming Zhu, Hairong Yue, and Bin Liang

Cite this: Adv. Sustainable Syst. 2018, 2, 1700165

https://doi.org/10.1002/adsu.201700165

Abstract:

A one-step strategy to obtain a high-performance catalyst from Cr(VI)-containing wastewater by the photoreduction process is described. ZrO2 is employed as a wide bandgap and high conduction-band photocatalyst to reduce, capture, and immobilize Cr(VI) ions under UV light irradiation. The byproduct of this step is used as a catalyst for the CO2 reverse water-gas shift (RWGS) reaction. The total Cr content in water decreases to 0.0413 mg·L−1 in 3 h, fulfilling the strictest wastewater standard. The soluble Cr(VI) species is converted into Cr(0) and Cr(III), and fixed on the ZrO2 surface to form Cr@ZrO2 as a byproduct with highly dispersed Cr species. Using this byproduct as a catalyst for the RWGS reaction results in almost thermal equilibrium conversion under 500 °C with 100% CO selectivity. This environment-friendly and economic strategy is very promising for controlling heavy metal pollution and comprehensive CO2 utilization.

本文介绍了一种利用光还原法从含铬废水中一步法获得高性能催化剂的方法。在紫外光照射下,ZrO2被用作宽禁带和高导带光催化剂来还原、捕获和固定Cr(VI)离子。副产品被用作CO2反水气转换(RWGS)反应的催化剂。水中总铬含量在3小时内降至0.0413 mg·L-1,符合最严格的废水标准。可溶性Cr(VI)转化为Cr(0)和Cr(III),固定在ZrO2表面,形成高分散Cr@ZrO2。利用该副产物作为反应催化剂,在500℃下反应几乎达到热平衡,CO选择性为100%。这一环境友好、经济的策略对控制重金属污染和二氧化碳综合利用具有重要意义。

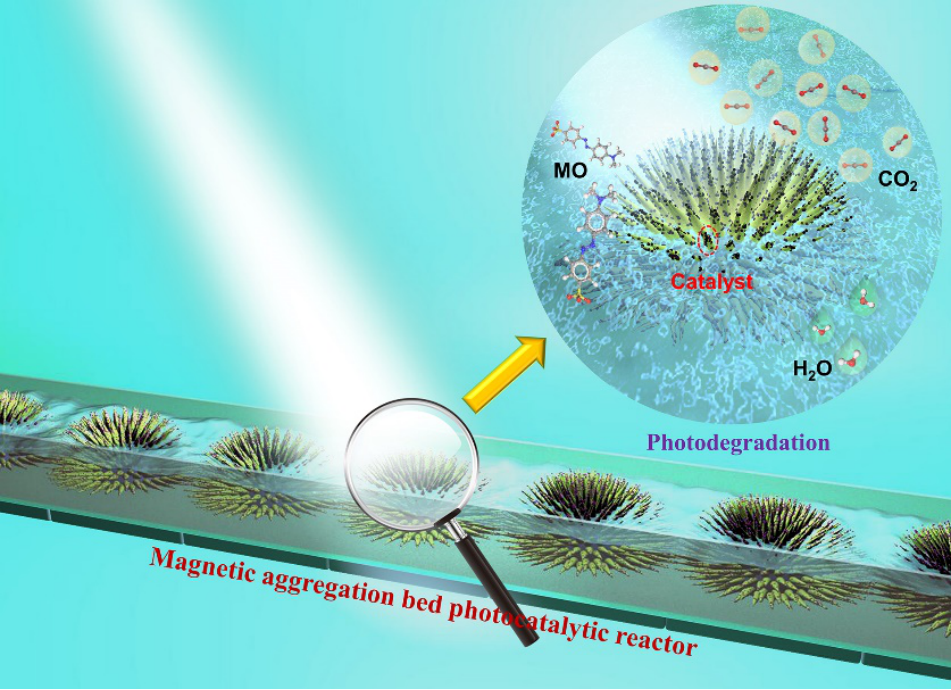

Magnetic Photocatalyst CoFe2O4-Ag2O with Magnetic Aggregation Bed Photocatalytic Reactor for Continuous Photodegradation of Methyl Orange

Fujin Sun, Jian He, Pan Wu, Qihui Zeng, Changjun Liu,Wei Jiang*

Cite this: Chemical Engineering Journal, Volume 397, 1 October 2020, 125397

https://doi.org/10.1016/j.cej.2020.125397

Abstract:

A magnetic aggregation bed photocatalytic reactor (MABPR) was designed and constructed to achieve continuous photodegradation of methyl orange (MO) solution without subsequent photocatalyst separation. A magnetic photocatalyst, CoFe2O4-Ag2O, was scattered and immobilized on aggregated flower-like Fe3O4 structures, which were anchored to the reactor with external magnets at the bottom. Under optimal operating conditions, MO is effectively photodegraded in the MABPR in 60 min with a fluid velocity of 0.01 m/s and a 100 mT magnetic field under natural illuminance (Ev). Magnetic aggregates in the MABPR support the magnetic photocatalyst, increasing their effective irradiation area and also increasing fluid disturbance to enhance mass transfer. Additional energy input for photodegradation and photocatalyst recovery were not required to operate the MABPR; the mass of photocatalyst did not decrease over the course of the experiment. The MABPR proposes a promising design for a usable, cost-effective, low-energy, continuous photoreactor using a magnetic photocatalyst.

设计并构造了磁性聚集床光催化反应器(MABPR),并实现了甲基橙(MO)溶液的连续降解,无需后续的光催化剂分离。将磁性光催化剂CoFe2O4-Ag2O分散并固定在聚集的花状Fe3O4结构上,该结构通过底部的外加磁场固定在反应器上。在最佳操作条件下(流速:0.01 m/s,磁场强度:100 mT),MO在自然光照下60分钟被完全降解。 MABPR中的磁性凝聚结构负载磁性光催化剂,增加了其光照面积,同时增强了流体扰动,进而增强了传质。MABPR不需要额外的能量输入来进行光降解和光催化剂回收;在整个实验过程中,光催化剂的质量并未降低。 MABPR为未来光催具体实用化提供了一种新的思路。

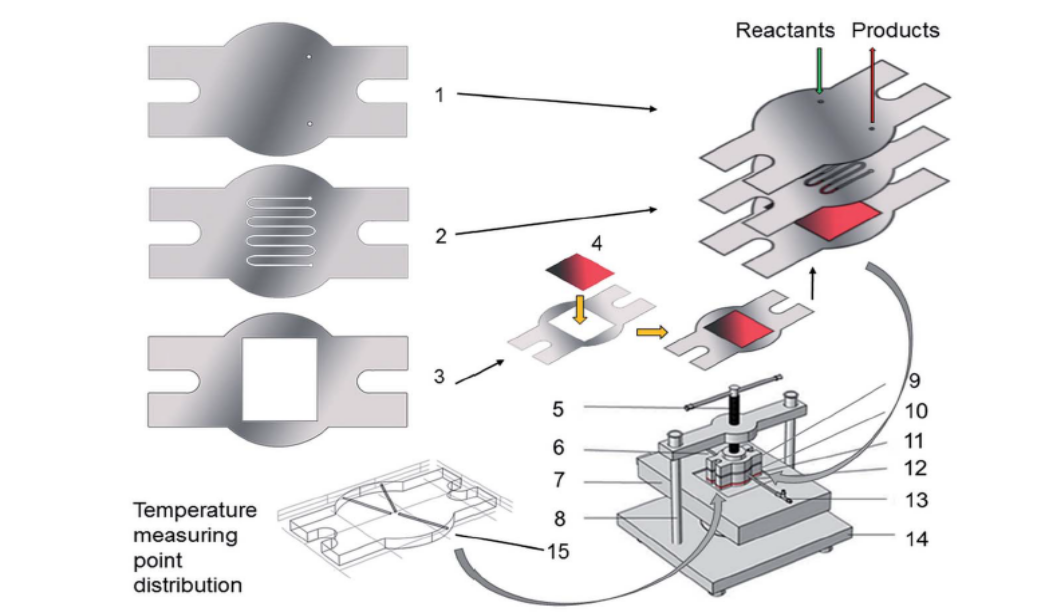

Wall-loaded Pt/TiO2/Ti catalyst and its application in ammonia oxidation reaction in microchannel reactor

Wei Jiang,* Jiaping Qiu, Wei Qiu, Shaojun Yuan, Houfang Lu and Bin Liang

Cite this: RSC Adv., 2016,6, 26637-26649

https://doi.org/10.1039/C6RA03993F

Abstract:

A microchannel reactor is a promising reactor type for industrial applications. However, loading heterogeneous catalysts in the microchannels is troublesome because of the high pressure drop and serious fluid flow abrasion. In this research, a home-made microchannel reactor was designed by using a wall-loaded Pt/TiO2/Ti catalyst as the microchannel wall. This wall-loaded Pt/TiO2/Ti catalyst was prepared by anodizing a Ti foil and photodepositing Pt on the anodic surface layer. The foil was then assembled as a side wall of the microchannel. Ammonia oxidation was used as the probe reaction for evaluating the performance of this microchannel reactor by using the wall-loaded catalyst. Simulation and experimental results show that 100% ammonia conversion can be obtained under the following conditions: temperature, 300 °C; gaseous hourly space velocity, 35 000 h−1; catalyst loading percentage, 85% of the total channel area; and ammonia to oxygen volume ratio, 1 : 13, in the absence of nitrogen, with a microchannel of length 80 mm, width 1.0 mm, and height 0.3 mm. Pressure drop in the microchannel is as small as 1.18 kPa, and temperature distribution is relatively uniform. Notably, NOx selectivity is significantly improved to become 88.32% at 300 °C. Simulations confirm that the selectivity showed such a high improvement owing to the short residence time of NOx because of the unique blind-hole structure of TiO2 nanotubes and the resulting large mass transfer resistance. The operation of this reactor with the wall-loaded Pt/TiO2/Ti catalyst is stable without any remarkable performance decay even after 360 h of operation. Hence, the microchannel reactor with a wall-loaded catalyst on the anodic metal is an attractive prospect for large-scale applications of rapid gas-to-solid exothermic reactions.

本研究以负载于壁面的Pt/TiO2/Ti催化剂为微通道壁,设计了国产微通道反应器。采用阳极氧化钛箔,在阳极表面层上光沉积铂,制备了负载于壁面的Pt/TiO2/Ti催化剂。然后将箔片组装成微通道的侧壁。以氨氧化为探针反应,采用负载型催化剂对该微通道反应器进行了性能评价。模拟和实验结果表明,在以下条件下可以获得100%的氨转化率: 温度,300℃,空速,35000h-1,催化剂装填率,占总通道面积的85%;而氨氧体积比为1:13,在不含氮的情况下,具有长80毫米、宽1.0毫米、高0.3毫米的微通道。微通道内压降小至1.18 kPa,温度分布较为均匀。值得注意的是,在300℃时,NOx选择性显著提高,达到88.32%。仿真结果表明,由于二氧化钛纳米管具有独特的盲孔结构和较大的传质阻力,使得NOx的停留时间短,选择性得到了很大的提高。负载Pt/TiO2/Ti催化剂的反应器运行360 h后,运行稳定,性能没有显著下降。因此,在阳极金属上加装壁面催化剂的微通道反应器是一种有吸引力的快速气体-固体放热反应的大规模应用前景。

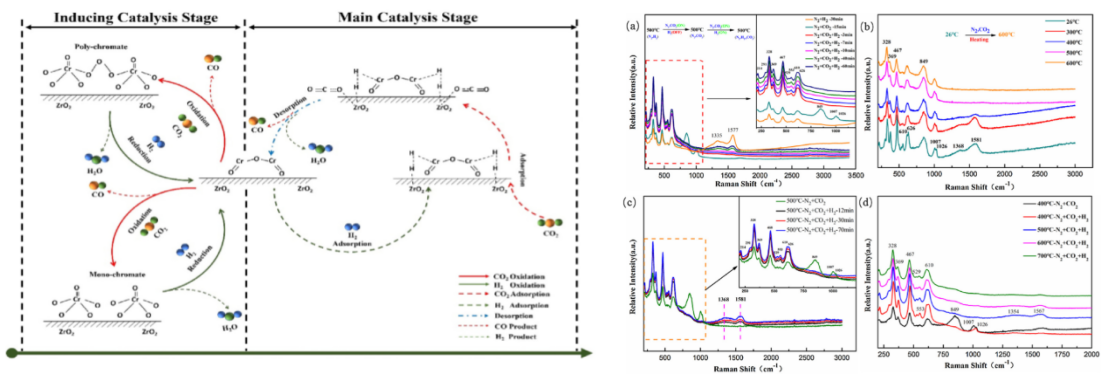

A highly selective Cr/ZrO2 catalyst for the reverse water-gas shift reaction prepared from simulated Cr-containing wastewater by a photocatalytic deposition process with ZrO2

Yang Taoa, Yingming Zhub, Changjun Liua, Hairong Yuea, Junyi Jia, Shaojun Yuana, Wei Jianga,⁎, Bin Lianga,b

Cite this: Journal of Environmental Chemical Engineering 6 (2018) 6761-6770

https://doi.org/10.1016/j.jece.2018.10.043

Abstract:

Here, we report the preparation of a Cr/ZrO2 composite catalyst for the reverse water-gas shift reaction (RWGS) that shows excellent low-temperature CO2 conversion and 100% CO selectivity. The catalyst was prepared from Cr-containing wastewater by photoreduction. Zirconia was used as a wide bandgap photocatalyst to photoreduce Cr(VI) under UV irradiation and immobilize the Cr species on the catalyst surface, resulting in a high dispersion. The results show that the obtained 1 wt%Cr/ZrO2 can catalyze the RWGS to reach the thermodynamic limit at 600 °C. The CO yield at 600 °C with photoreduced Cr/ZrO2 after calcination, 38.34%, is significantly higher than that of the catalyst prepared by impregnation. Metal hydrides were determined to be the key intermediates in the RWGS reaction with Cr/ZrO2 as the catalyst, and the cyclic conversion between Cr(VI) and Cr(III) caused by the hydrogen reduction and CO2 oxidation improves the catalytic activity. This study provides a strategy to acquire a promising RWGS catalyst for CO2 emission reduction and utilization and an attractive method to treat Cr-containing wastewater.

通过光还原从含铬废水中制备Cr/ZrO2复合催化剂,氧化锆用作宽带隙光催化剂,可在紫外线照射下光还原Cr(VI),并将Cr物种固定在催化剂表面,从而获得高分散度。结果表明,所获得的1wt%Cr/ZrO2可以催化RWGS达到600℃的热力学极限。煅烧后光还原的Cr/ZrO2在600°C时的CO收率高达38.34%,明显高于浸渍法制备的催化剂。确定了在RWGS反应中以Cr/ZrO2为催化剂的重要中间体为金属氢化物,氢还原和CO2氧化引起的Cr(VI)和Cr(III)之间的循环转化提高了催化活性。这项研究提供了一种策略,以期获得一种有前途的RWGS催化剂以减少并利用CO2,提供了一种有吸引力的处理含铬废水的方法

Continuous Biodiesel Production Catalyzed by Trace-Amount Alkali under Methanol Subcritical Conditions

Wei Jiang,* Hong Zou, Chengyu Fu, Jiao Lei, Houfang Lu, and Bin Liang

Cite this: Ind. Eng. Chem. Res. 2014, 53, 33, 12971-12982

https://pubs.acs.org/doi/full/10.1021/ie501969k

Abstract:

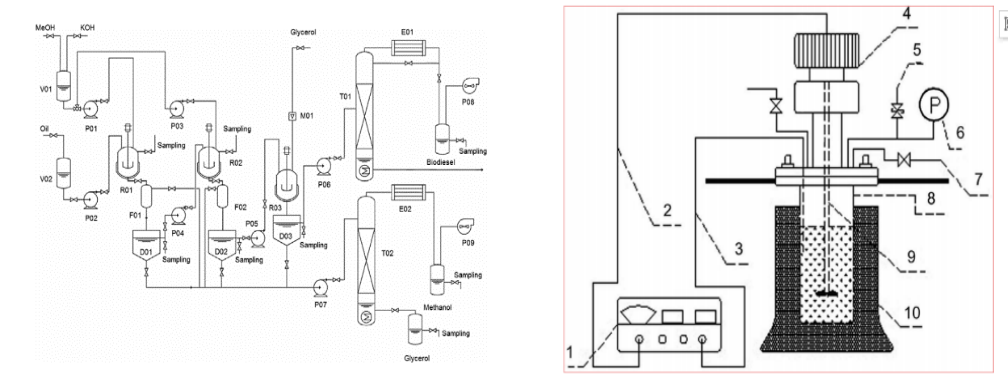

Biodiesel is a promising alternative biofuel, but the treatment of wastewater containing alkali catalyst and glycerol discharged from the washing unit operation increases the cost significantly. Here a novel continuous biodiesel production process with trace-amount alkali as the catalyst under the methanol subcritical condition was proposed and investigated. The optimal operation conditions of preliminary batch reaction experiment are temperature of 200 °C, catalyst concentration of 513 mg/kg, reaction time of 38 min, molar ratio of methanol to oil of 1, and system pressure of 1.5 MPa. The one-step conversion of raw oil in a batch reactor can reach up to 85.5%. The alkali residue in the biodiesel product can be further reduced by removing the methanol and washing by glycerol instead of by acid or water. The optimal weight ratio of glycerol to biodiesel is 1.5:1, and the residual alkali in the final ester product is about 4.6 mg/kg. The simulation and bench scale continuous experiment based on the optimal batch operation parameters confirmed that the biodiesel produced by the process is qualifified well up to the Chinese standard of biodiesel, and the K+ concentration in biodiesel was less than 3.0 mg/kg. The economic evaluation showed that this new process is more economically feasible than the traditional processes.

本研究针对生物柴油洗涤装置运行过程中产生的含碱催化剂和甘油废水的问题,提出并研究了甲醇亚临界条件下以痕量碱为催化剂连续生产生物柴油的新工艺,并在间歇式反应器中找到了最佳操作条件,一次转化率可达85.5%。并且通过脱去甲醇、用甘油代替酸或水洗涤,进一步降低生物柴油产品中的碱残留量——碱约为4.6mg/kg,K+浓度小于3.0mg/kg。实验结果表明所得柴油符合国家标准;经济评价表明新工艺比传统工艺具有更大的经济可行性。

Low-Temperature Ammonia Oxidation in a Microchannel Reactor with Wall-Loaded X(X = Pt, Pd, Rh, PtPdRh)/TiO2 Nanotube Catalysts

Qiang Liu, Wei Qiu, Pan Wu, Hairong Yue, Changjun Liu, Wei Jiang*

Cite this: Ind. Eng. Chem. Res. 2019, 58, 23, 9819-9828

https://doi.org/10.1016/j.apsusc.2014.04.047

Abstract:

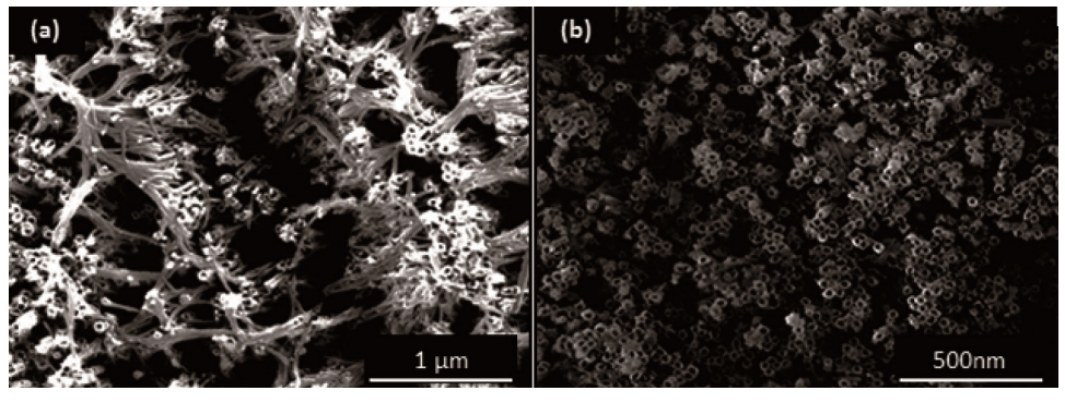

Anodization process is a facile method to prepare structured nano-material. In this research, anodization process of zirconium in (NH4)2SO4/NH4F solution was studied systematically and the anodized zirconia was applied to degrade methyl orange (MO) solution under UV irradiation and compared with anodized titania nanotubes to determine the photoactivity of zirconia nanotubes. After anodization in aqueous electrolyte containing 1 M (NH4)2SO4 and 0.25 wt% NH4F for 120 min at 20V, zirconia nanotubes (ZNT) with diameters of about 20 nm and lengths of about 600 nm were formed. The growth mechanism of ZNT was studied with SEM and TEM. The hypothesis of ZNT growth, in which electric etching process startedat the pits and further to deepen in situ to form nanotubes, was confifirmed by the SEM.

本研究采用阳极氧化法利用(NH4)2SO4/NH4F溶液制备出氧化锆纳米管材料,并将氧化锆应用于甲基橙(MO)光降解以确定氧化锆纳米管的光活性。在本实验条件下,最终获得直径约为20nm、长度约为600 nm的氧化锆纳米管(ZNT)。扫描电镜和透射电镜显示,电蚀刻工艺从凹坑处开始,在原位进一步深化形成纳米管。表征结果显示生长的ZNT为单斜和正方ZrO2晶体结构,在300℃退火后转变为纯单斜结构。未退火的ZNT具有良好的光催化性能,4h后MO光降解率为94.45%,所得产物的6此循环稳定性良好。